Exporting shrimp isn’t just about catching and freezing—it’s a science-driven operation where every step matters. The process of packaging and shipping shrimp for export demands strict hygiene, temperature control, and regulatory compliance to ensure the product reaches international markets in peak condition. From harvesting at the right moment to using advanced freezing methods like IQF (Individual Quick Freezing), exporters must follow protocols that preserve freshness, texture, and safety.

Packaging materials must be food-grade and resistant to moisture and oxygen, while labeling must meet the traceability standards of importing countries. Logistics also play a critical role, with cold chain integrity being non-negotiable. Whether you’re targeting the EU, US, or Asian markets, mastering this process is essential for long-term success. In this article, we’ll walk through the latest scientific and practical steps involved in the process of packaging and shipping shrimp—so keep reading to discover how top exporters stay ahead.

Harvesting Shrimp at Peak Quality: Timing Is Everything

The foundation of a successful export begins with harvesting shrimp at the right moment. Shrimp must be collected when they reach optimal size and health, typically between 20–25 grams for export-grade batches. Delayed harvesting can lead to overgrowth, texture degradation, and increased mortality during transport.

At Pishva Holding, harvesting protocols are aligned with international aquaculture standards. Shrimp are collected using low-stress netting systems and immediately transferred to chilled tanks to preserve freshness. Timing is critical—not just for quality, but for aligning with the downstream process of packaging and shipping shrimp.

Key harvesting factors:

- Size grading: Ensures uniformity for packaging

- Water temperature: Should be below 20°C during harvest

- Handling time: Less than 2 hours from pond to processing

By optimizing harvest timing, exporters reduce spoilage risk and improve yield—making the entire process of packaging and shipping shrimp more efficient and profitable.

Initial Washing and Sorting: The First Line of Quality Control

Once harvested, shrimp undergo immediate washing and sorting to remove mud, shells, and biological contaminants. This step is essential for preserving organoleptic quality and meeting international hygiene standards. Iranian Shrimp Supplier & Wholesale facilities often use ozone-treated water or chlorinated rinses to sanitize the product without compromising texture.

Sorting is typically done by automated grading machines that classify shrimp by size and appearance. This ensures consistency in packaging and helps meet buyer specifications in markets like Japan, the EU, and the US.

Best practices for washing and sorting:

- Use potable or treated seawater for rinsing

- Maintain water temperature between 0–4°C

Implement visual inspection and mechanical grading

This stage directly impacts the success of the process of packaging and shipping shrimp. Clean, well-sorted shrimp reduce rejection rates and enhance shelf life.

Pre-Processing and Deheading: Hygiene Meets Efficiency

Pre-processing involves removing heads, shells, and veins from shrimp, depending on the export format (e.g., HOSO, HLSO, PUD). This step must be done under strict hygiene protocols to prevent microbial contamination. A reliable shrimp supplier will follow HACCP and ISO 22000 standards to ensure food safety.

Deheading is typically done manually or with precision machines. The shrimp are kept at 0–4°C throughout to maintain texture and prevent spoilage. Facilities often use stainless steel surfaces and UV-sterilized tools to minimize contamination.

Hygiene protocols include:

- Regular swab testing of surfaces

- Use of food-grade gloves and aprons

- Daily sanitation of equipment

Proper pre-processing ensures that the process of packaging and shipping shrimp meets global standards. It also improves presentation and reduces weight loss during freezing.

Advanced Freezing Techniques: Preserving Texture and Taste

Freezing is the most critical step in preserving shrimp for export. The industry standard is IQF (Individual Quick Freezing), which freezes each shrimp separately to prevent clumping and maintain texture. Leading systems like OctoFrost and Palinox use cyclone tunnels and forced-air technology to reach -18°C in under 15 minutes.

Benefits of IQF freezing:

- Maintains natural appearance

- Prevents ice crystal damage

- Allows portion control for end users

| Freezing Method | Time to -18°C | Texture Retention |

| IQF | ~15 min | High |

| Block Freezing | ~2–3 hrs | Moderate |

Advanced freezing ensures the process of packaging and shipping shrimp delivers a premium product to global markets. Exporters who invest in these technologies gain a competitive edge in quality and shelf life.

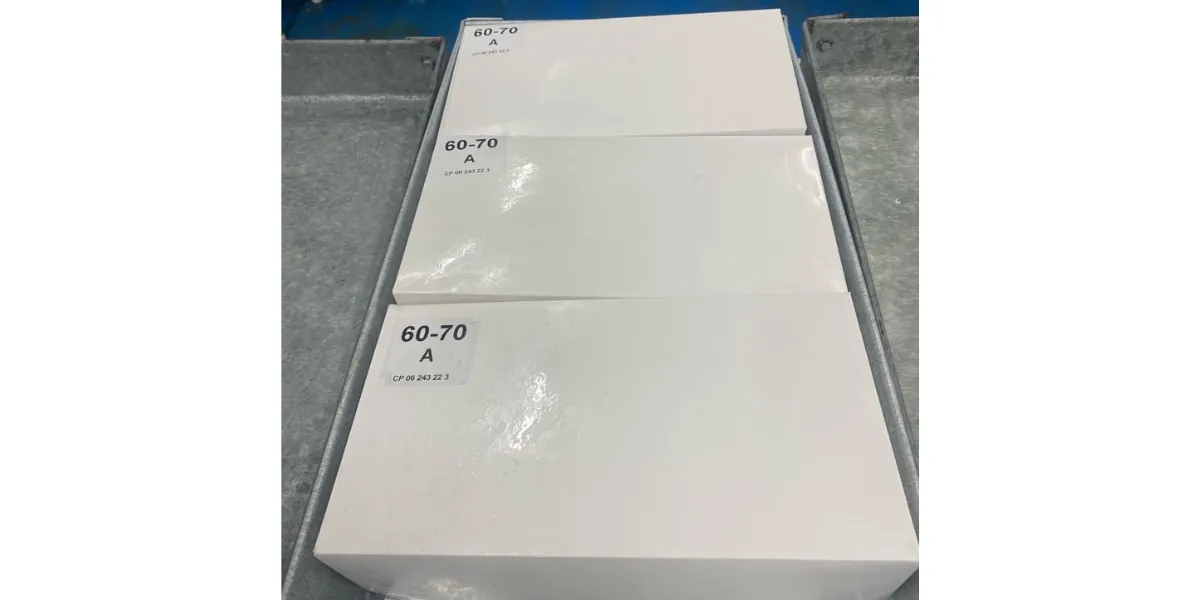

Packaging for Export: Materials, Methods, and Market Requirements

Packaging shrimp for export involves more than just sealing a bag—it’s about preserving quality, meeting legal standards, and ensuring traceability. Export-grade packaging uses multilayer films with oxygen and moisture barriers. Vacuum sealing or Modified Atmosphere Packaging (MAP) is preferred for longer shelf life.

Labeling must include:

- Product type and format (e.g., HLSO)

- Country of origin

- Production and expiry dates

- Batch number and traceability code

| Packaging Type | Shelf Life | Market Preference |

| Vacuum Seal | 12–18 mo | EU, US |

| MAP | 10–14 mo | Asia, Middle East |

Proper packaging is the final safeguard in the process of packaging and shipping shrimp.

Quality Assurance and Microbiological Testing: Meeting Global Standards

Ensuring product safety is non-negotiable in the process of packaging and shipping shrimp. Quality assurance (QA) begins at the farm and extends through every stage of processing. According to FAO and Eurofins Scientific, microbiological testing is a core component of QA, targeting pathogens like Vibrio spp., Salmonella, and E. coli.

Key QA protocols include:

- Implementation of HACCP (Hazard Analysis and Critical Control Points)

- Routine swab testing of surfaces and equipment

- Batch-level microbial testing before export

| Test Type | Target Organism | Frequency |

| Microbial Load | Total Plate Count | Every batch |

| Pathogen Screening | Salmonella, E. coli | Weekly |

| Residue Analysis | Antibiotics, Heavy Metals | Monthly |

ISO 22000 and BRC certifications are often required by importers in the EU and North America. These frameworks ensure that the process of packaging and shipping shrimp meets international food safety benchmarks. By investing in robust QA systems, exporters reduce rejection risks and build long-term trust with global buyers.

Regulatory Compliance and Export Documentation

Navigating export regulations is a critical step in the process of packaging and shipping shrimp. Each destination country has its own set of documentation and certification requirements. For example, the U.S. FDA mandates prior notice filings and compliance with the Fish and Fishery Products Hazards and Controls Guidance.

Essential export documents include:

- Health Certificate (issued by veterinary authorities)

- Certificate of Origin

- HACCP Compliance Certificate

- Aquaculture Stewardship Council (ASC) or GlobalG.A.P. Certification

| Document | Purpose |

| Health Certificate | Confirms product safety and hygiene |

| Certificate of Origin | Verifies country of production |

| FDA Prior Notice (US) | Required for all seafood imports |

Exporters must also comply with the EU’s TRACES system and Japan’s Positive List System. Failing to meet these standards can result in shipment rejections or bans. Therefore, regulatory compliance is not just a formality—it’s a strategic pillar in the process of packaging and shipping shrimp.

Cold Chain Logistics: Maintaining -18°C from Plant to Port

Maintaining a continuous cold chain is essential to preserving shrimp quality during export. The process of packaging and shipping shrimp relies heavily on keeping the product at or below -18°C from the processing plant to the final destination.

Cold chain essentials:

- Use of reefer containers with digital temperature control

- Real-time monitoring via data loggers and GPS

- Backup power systems during transit

| Cold Chain Stage | Target Temp | Monitoring Method |

| Processing Facility | -18°C | Manual + digital logs |

| Transport to Port | -18°C | Reefer truck sensors |

| Ocean Freight | -18°C | Reefer container logs |

Companies like Maersk and CEVA Logistics offer specialized seafood logistics solutions that ensure temperature integrity. Any break in the cold chain can lead to bacterial growth and spoilage, making this step one of the most critical in the process of packaging and shipping shrimp.

Sustainable and Ethical Sourcing: A Growing Export Imperative

Sustainability is no longer optional—it’s a market expectation. In the process of packaging and shipping shrimp, sourcing practices are under increasing scrutiny from buyers and regulators. Certifications like ASC, BAP, and GlobalG.A.P. validate that shrimp are farmed with minimal environmental impact and fair labor practices.

Sustainable sourcing practices include:

- Avoiding mangrove deforestation

- Using feed from certified sustainable sources

- Ensuring fair wages and safe working conditions

| Certification | Focus Area |

| ASC | Environmental & social |

| BAP | Hatchery, feed, farm, plant |

| GlobalG.A.P. | Farm-level sustainability |

According to the Global Shrimp Forum 2025, retailers increasingly demand proof of ethical sourcing before placing large orders. Integrating sustainability into the process of packaging and shipping shrimp not only protects ecosystems but also opens doors to premium markets.

Digital Traceability and Blockchain in Shrimp Export

Traceability is transforming the seafood industry. In the process of packaging and shipping shrimp, blockchain technology is being adopted to ensure transparency, prevent fraud, and meet buyer demands.

Blockchain benefits include:

- Immutable records of origin, processing, and transport

- Real-time access for buyers and regulators

- Enhanced recall efficiency in case of contamination

| Feature | Benefit |

| QR-coded packaging | Consumer transparency |

| Smart contracts | Automated compliance checks |

| Cloud-based ledgers | Global access and auditability |

Platforms like FoodTraze are already helping shrimp exporters in India and Southeast Asia meet EU and US traceability standards. By integrating blockchain into the process of packaging and shipping shrimp, exporters gain a competitive edge in trust, compliance, and market access.

Final Thoughts: Why Mastering Shrimp Export Logistics Is a Competitive Advantage

In today’s global seafood trade, precision and consistency are the pillars of successful shrimp export. The process of packaging and shipping shrimp is no longer a routine task—it’s a strategic operation that blends food science, logistics, and international compliance. Exporters who invest in high-efficiency freezing systems, smart packaging technologies, and robust cold chain logistics are better positioned to meet the rising expectations of global buyers. Moreover, adhering to certifications like HACCP, ASC, and ISO 22000 not only ensures product safety but also builds trust in competitive markets.

As consumer demand shifts toward transparency and sustainability, integrating digital traceability into your export workflow becomes a game-changer. Ultimately, the process of packaging and shipping shrimp isn’t just about moving a product—it’s about delivering quality, reliability, and value across borders. If you’re serious about scaling your shrimp export business, mastering these steps is not optional—it’s essential. Let’s dive deeper into each stage and explore how you can optimize your operations for global success.

FAQ

1. What is the ideal temperature for shipping frozen shrimp? The recommended temperature is -18°C or lower throughout the cold chain.

2. Which certifications are required for shrimp export to the EU? HACCP, ASC, and a valid Health Certificate are typically required.

3. How does blockchain improve shrimp traceability? It creates tamper-proof records of every step in the supply chain, from farm to port.

4. What are the main microbiological tests for shrimp export? Tests for Salmonella, E. coli, Vibrio spp., and total plate count are standard.

5. Why is sustainability important in shrimp export? It ensures long-term viability, meets buyer expectations, and opens access to premium markets.