Nothing impacts shrimp quality more than how it’s handled after harvest. If you’re aiming for international markets, mastering the science of storing and freezing shrimp isn’t optional—it’s essential. From the moment shrimp leave the water, they begin to degrade. Without precise temperature control and hygienic processing, exporters risk spoilage, bacterial growth, and rejection at customs. That’s why global seafood leaders rely on proven preservation methods like IQF (Individually Quick Frozen), brine freezing, and vacuum packaging to lock in freshness and meet strict import standards.

Whether you’re exporting to Europe, Asia, or North America, understanding the nuances of shrimp storage—from chilling protocols to cold chain logistics—can make or break your business. In this guide, we’ll walk through the most effective, scientifically backed techniques for storing and freezing shrimp, tailored for exporters who want to stay competitive. Keep reading to discover how to preserve quality, extend shelf life, and meet global compliance with confidence.

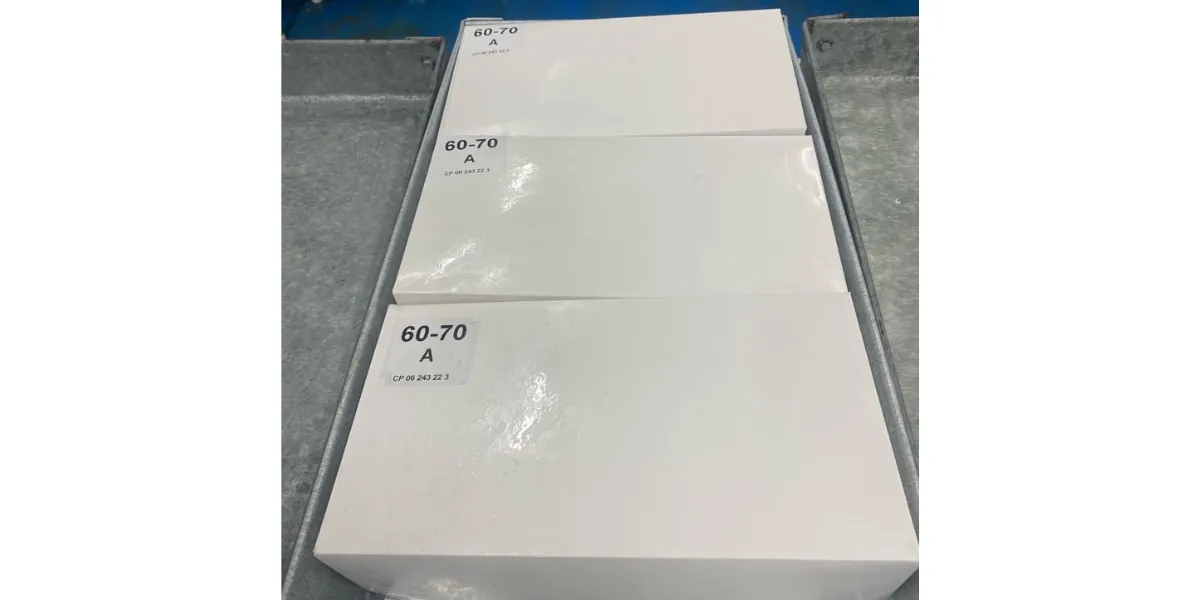

Pre-Freezing Essentials: Sorting, Cleaning, and De-heading

Before any shrimp enters the freezing stage, it must undergo rigorous pre-processing to ensure quality and compliance with export standards. This phase is critical in the storing and freezing shrimp workflow, as improper handling can lead to microbial growth, texture loss, and reduced shelf life.

Key steps include:

- Sorting by size and species: Uniformity ensures consistent freezing and packaging.

- Cleaning: Shrimp are washed to remove sand, shell fragments, and surface bacteria.

- De-heading and peeling: Depending on buyer requirements, shrimp may be de-headed and peeled to reduce enzymatic activity and improve presentation.

| Step | Purpose | Impact on Quality |

| Sorting | Size uniformity | Even freezing, better grading |

| Cleaning | Remove contaminants | Reduces spoilage risk |

| De-heading | Enzymatic control | Enhances shelf life |

Companies like Pishva Holding emphasize these steps in their export protocols, ensuring shrimp meet EU and FDA standards. By investing in proper pre-freezing techniques, exporters can maintain product integrity and reduce rejection rates. This stage sets the foundation for successful storing and freezing shrimp operations.

Chilling vs. Freezing: Understanding the Temperature Thresholds

Temperature control is the backbone of shrimp preservation. In the context of storing and freezing shrimp, knowing when to chill and when to freeze is essential for maintaining freshness and safety.

- Chilling (0–4°C) is used for short-term holding during transport to processing facilities. It slows bacterial growth but doesn’t halt enzymatic activity.

- Freezing (-18°C or lower) is mandatory for long-term export. It stops microbial and enzymatic processes, preserving texture and flavor.

| Method | Temperature Range | Use Case | Shelf Life |

| Chilling | 0–4°C | Short-term transport | 1–2 days |

| Freezing | -18°C or lower | Export and long-term hold | 6–12 months |

According to Iranian Shrimp Supplier & Wholesale standards, frozen shrimp must be stored at a consistent -18°C to meet international quality benchmarks. Deviations can lead to freezer burn, texture degradation, and microbial risks. Proper chilling and freezing protocols are not just technical—they’re strategic tools in global shrimp trade.

IQF (Individually Quick Frozen): The Gold Standard for Export

IQF technology has revolutionized the storing and freezing shrimp process. Unlike block freezing, IQF freezes each shrimp individually, preserving its natural shape, texture, and flavor.

Advantages of IQF:

- Rapid freezing prevents large ice crystals, which damage tissue.

- Individual freezing avoids clumping, making shrimp easier to portion and cook.

- Reduced dehydration maintains moisture and minimizes freezer burn.

| Feature | Benefit |

| Rapid freezing | Preserves texture and flavor |

| Individual freezing | Easier handling and packaging |

| Moisture retention | Better taste and appearance |

IQF shrimp are highly valued in markets focused on health benefits of shrimp, as the method retains nutrients like omega-3s, selenium, and protein. Exporters using IQF can command premium prices and meet the expectations of health-conscious consumers. It’s not just a freezing method—it’s a quality guarantee.

Brine Freezing: Enhancing Texture and Shelf Life

Brine freezing is a specialized technique used in storing and freezing shrimp, especially for markets that prefer enhanced flavor and texture. Shrimp are immersed in chilled brine (typically 3–5% salt concentration), which accelerates freezing and improves moisture retention.

Benefits of brine freezing:

- Faster freezing reduces drip loss and bacterial risk.

- Salt infusion enhances taste and reduces enzymatic spoilage.

- Improved texture makes shrimp more appealing post-thaw.

| Technique | Description | Effect on Shrimp |

| Immersion method | Shrimp submerged in chilled brine | Uniform freezing, salt uptake |

| Shower method | Brine sprayed over shrimp | Faster freezing, less salt |

Used widely in Asia and the Middle East, brine freezing is ideal for bulk exports and value-added products. Studies show that shrimp frozen via brine retain better texture and color after thawing. For exporters seeking efficiency and quality, brine freezing is a smart addition to their preservation toolkit.

Packaging Protocols: Vacuum Sealing and Modified Atmosphere

Effective packaging is a cornerstone of storing and freezing shrimp for export. It not only protects the product from physical damage but also preserves freshness and extends shelf life. Two widely adopted methods are vacuum sealing and Modified Atmosphere Packaging (MAP).

Vacuum sealing removes air from the package, minimizing oxidation and microbial growth. This method is ideal for frozen shrimp, as it prevents freezer burn and maintains moisture.

MAP replaces air with gases like nitrogen or carbon dioxide, creating an environment that slows spoilage. It’s especially useful for chilled shrimp intended for short-term distribution.

| Packaging Method | Key Benefit | Shelf Life Impact |

| Vacuum Sealing | Prevents oxidation & drying | Extends by 30–50% |

| MAP | Controls microbial activity | Ideal for chilled exports |

According to Eurofish and Navire Logistics, these protocols are essential for meeting international standards. When integrated into the storing and freezing shrimp process, they ensure product integrity from factory to shelf.

Hygiene and HACCP Compliance: Critical for Export Approval

No matter how advanced your freezing technology is, without strict hygiene and HACCP compliance, your shrimp won’t pass export inspections. In the storing and freezing shrimp workflow, sanitation and safety protocols are non-negotiable.

HACCP (Hazard Analysis and Critical Control Points) is a globally recognized system that identifies and controls food safety risks. Shrimp exporters must document every step—from harvesting to packaging—to ensure traceability and compliance.

Key certifications include:

- HACCP Certification

- Health Certificate

- GlobalG.A.P.

- ASC (Aquaculture Stewardship Council)

| Certification | Purpose | Required For |

| HACCP | Food safety control | All export markets |

| Health Certificate | Sanitary compliance | EU, US, Asia |

| ASC | Sustainable aquaculture | Premium buyers |

As noted by Nghi Son Foods Group and FDA, these certifications are essential for legal clearance and brand reputation. Hygiene isn’t just a checklist—it’s the backbone of successful storing and freezing shrimp operations.

Cold Chain Logistics: Maintaining Integrity from Dock to Destination

Cold chain logistics ensures that shrimp remain safe and high-quality from harvest to delivery. In the storing and freezing shrimp process, maintaining a consistent temperature is vital to prevent spoilage and bacterial growth.

Key components of cold chain logistics:

- Refrigerated transport (0–4°C for chilled, -18°C for frozen)

- Real-time temperature monitoring

- GPS tracking for route optimization

- Backup power systems in case of failure

| Stage | Temperature Range | Risk if Broken |

| Harvest to dock | 0–4°C | Bacterial growth |

| Freezing & storage | -18°C | Texture degradation |

| Export transit | -18°C | Rejection at customs |

Thawing Guidelines for End Users: Preserving Quality Post-Export

Even the best storing and freezing shrimp methods can be undone by poor thawing. That’s why exporters must educate end users on proper thawing techniques to preserve texture, flavor, and safety.

Recommended thawing methods:

- Refrigerator thawing (0–4°C): Slow and safe, ideal for maintaining quality.

- Cold water thawing: Submerge sealed shrimp in cold water, changing water every 30 minutes.

- Avoid room temperature thawing: Promotes bacterial growth and texture loss.

| Method | Time Required | Quality Impact |

| Refrigerator thawing | 12–24 hours | Best texture retention |

| Cold water thawing | 1–2 hours | Good, if monitored |

| Room temp thawing | Unsafe | Risk of contamination |

Final Thoughts: Why Precision in Shrimp Preservation Pays Off

Exporting shrimp isn’t just about catching and packaging—it’s about preserving perfection. The difference between a rejected shipment and a premium product often lies in how well you manage storing and freezing shrimp. Techniques like IQF freezing, brine immersion, and vacuum sealing aren’t just industry buzzwords—they’re scientifically proven methods that protect texture, flavor, and safety. When combined with HACCP protocols and cold chain monitoring, these strategies ensure your shrimp arrive fresh, compliant, and ready for market.

But it doesn’t end there. Educating buyers on proper thawing and handling completes the preservation cycle, reinforcing your brand’s reputation for quality. In a global seafood market where competition is fierce and standards are high, investing in smart preservation isn’t a luxury—it’s a necessity. By applying the right methods, you’re not just storing shrimp—you’re storing trust, consistency, and long-term success. Ready to elevate your export game? Let’s dive deeper into the techniques that make it happen.

FAQ

Q1: What’s the ideal temperature for storing and freezing shrimp? A: For long-term export, shrimp should be frozen at -18°C or lower. Chilling (0–4°C) is only suitable for short-term holding.

Q2: How does vacuum sealing help shrimp preservation? A: It removes oxygen, preventing oxidation and freezer burn, which extends shelf life and maintains texture.

Q3: Why is HACCP certification important for shrimp exporters? A: It ensures food safety compliance, traceability, and acceptance in international markets.

Q4: What’s the safest way to thaw frozen shrimp? A: Thawing in the refrigerator (0–4°C) is safest and best for preserving quality.

Q5: Can poor cold chain logistics affect shrimp quality? A: Yes. Temperature fluctuations can cause spoilage, texture loss, and rejection at customs.